What we do and produce?

As a manufacturer at international standarts, we, Novotech Biomedical have significant experience in the design, development and production of medical devices.

Our highly experienced crew works with customers during product design, mold design and process development. When we combine this value-added working understanding with our molding and injection manufacturing experience, we are able to manufacture even the most unique medical devices.

We produce advanced medical plastic injection and medical extrusion in the cleanroom. Our capabilities include design engineering services and finished contract product services.Our products are produced in ISO 13485 certified facilities under sturdy quality management services. (QMS)

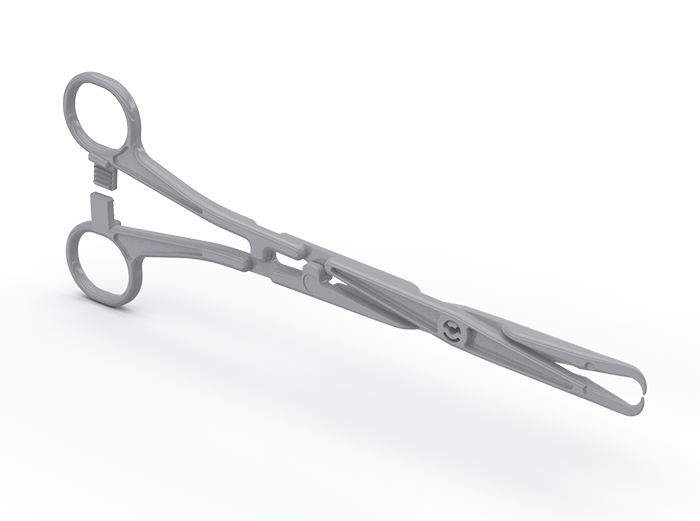

Product Design

We respond to the needs in the medical sector in countries around the world and Turkey with our experience and innovative design with “economical, qualified and functional” product designs.

Thanks to our knowledge of medical grade engineering plastics, we evaluate the requirements of your medical product (physical properties,sterilization and biocompatibility etc.) with you and make suggestions in your raw material choices.

Technically necessary designed products are physically checked with 3D printing methods.

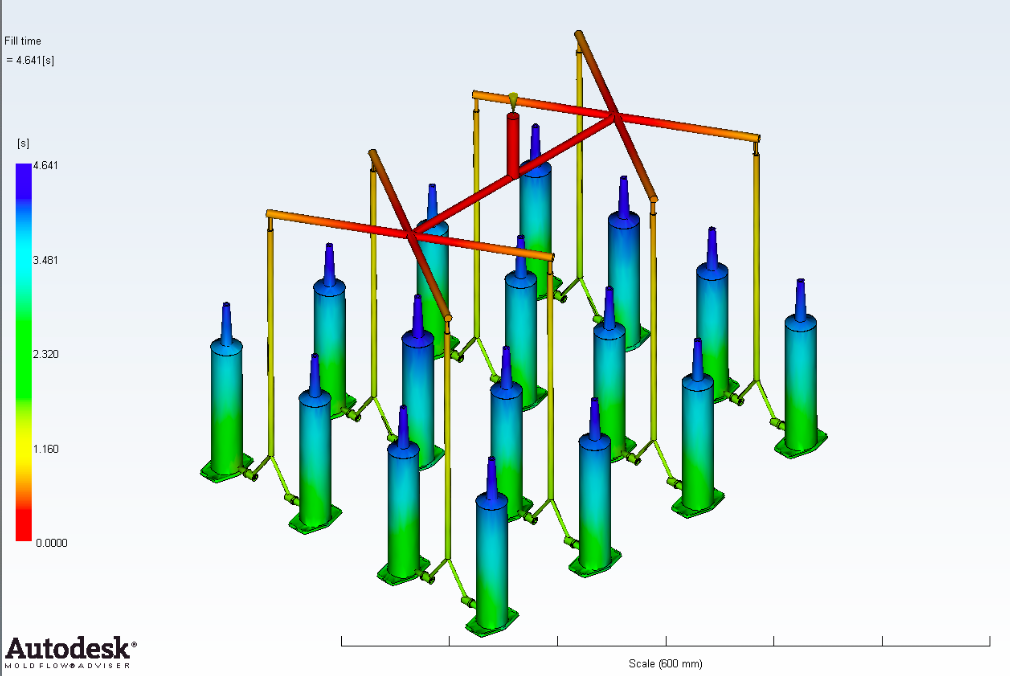

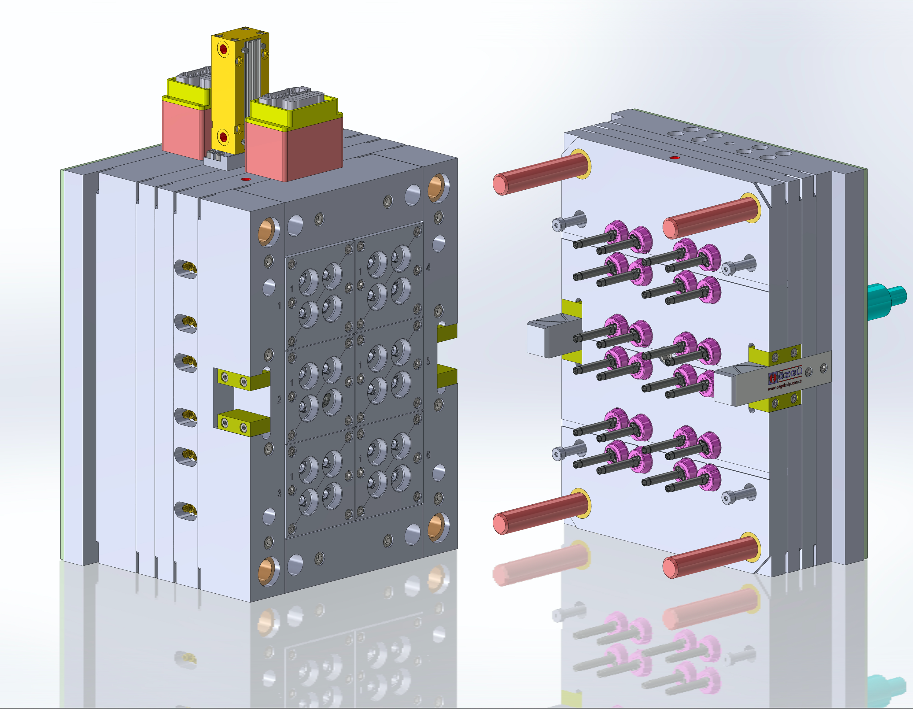

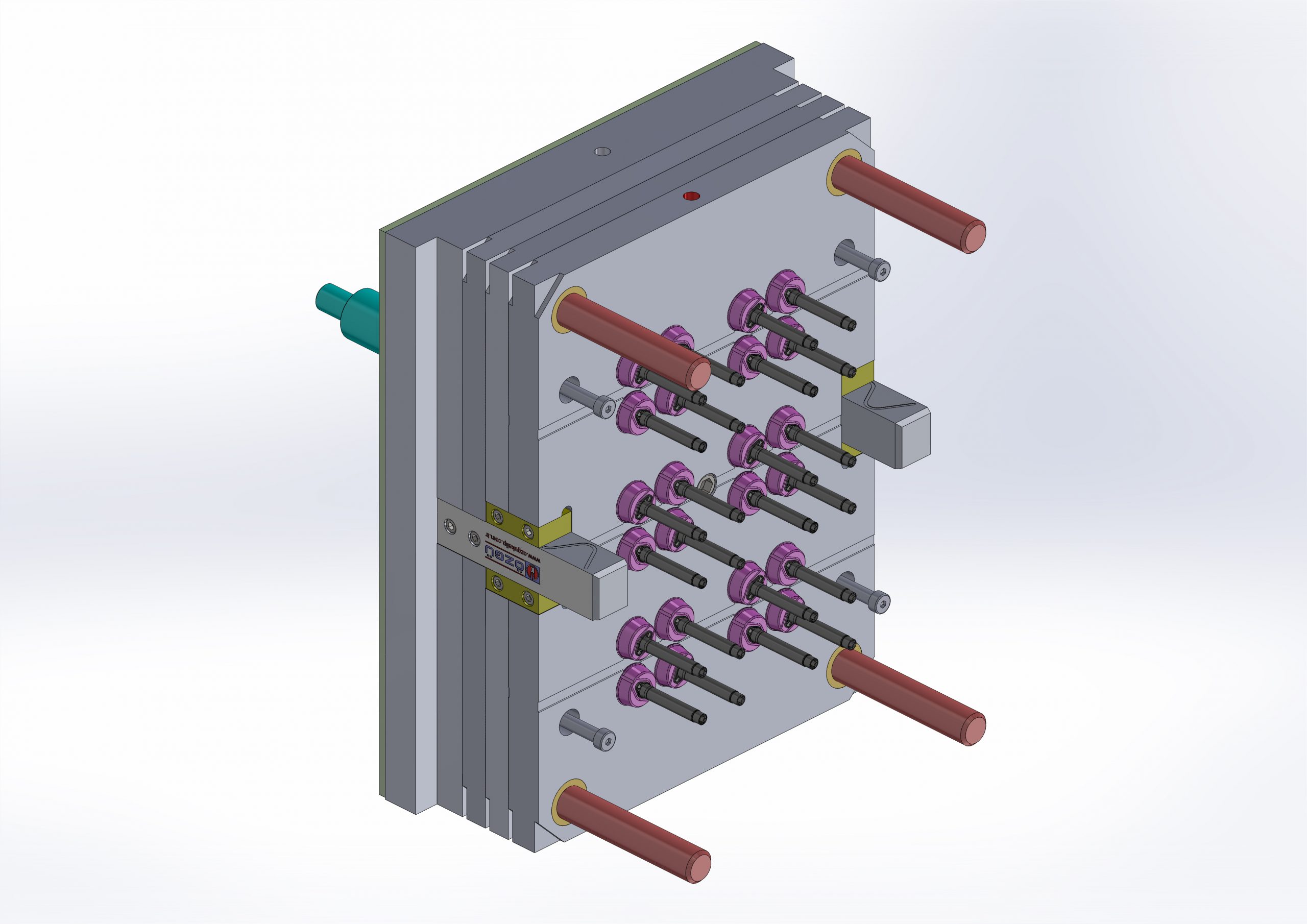

Mold Design and Manufacturing

We provide services to you in the following subjects as Novotech Biomedical.

- Mold Design,

- Prototype Mold Manufacturing

- Final Mold Manufacturing

- Pilot Production in the controlled-area.

We work with expert mold designers and experienced manufacturing technic crew to ensure the best mold design and long mold life in the finished product.

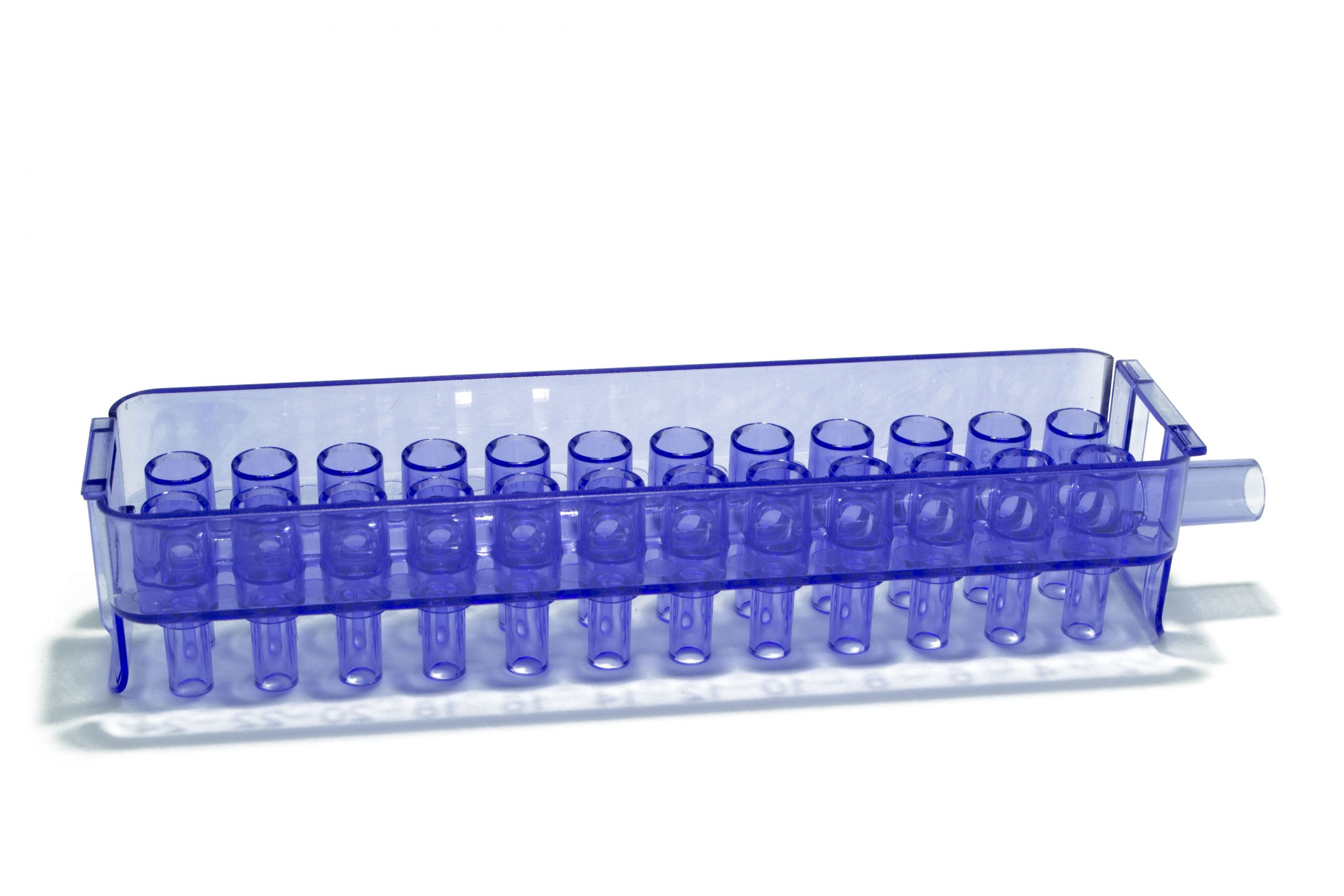

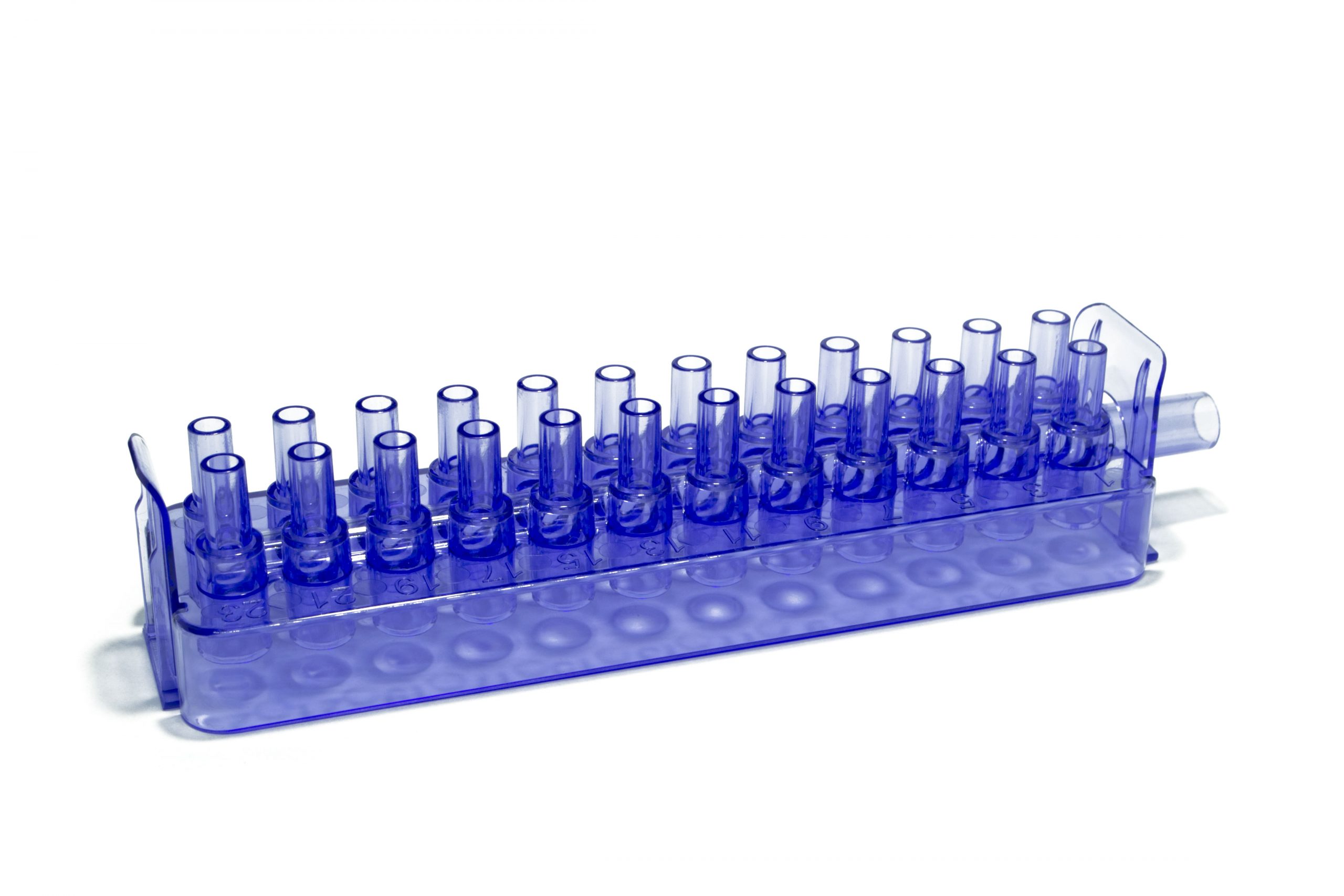

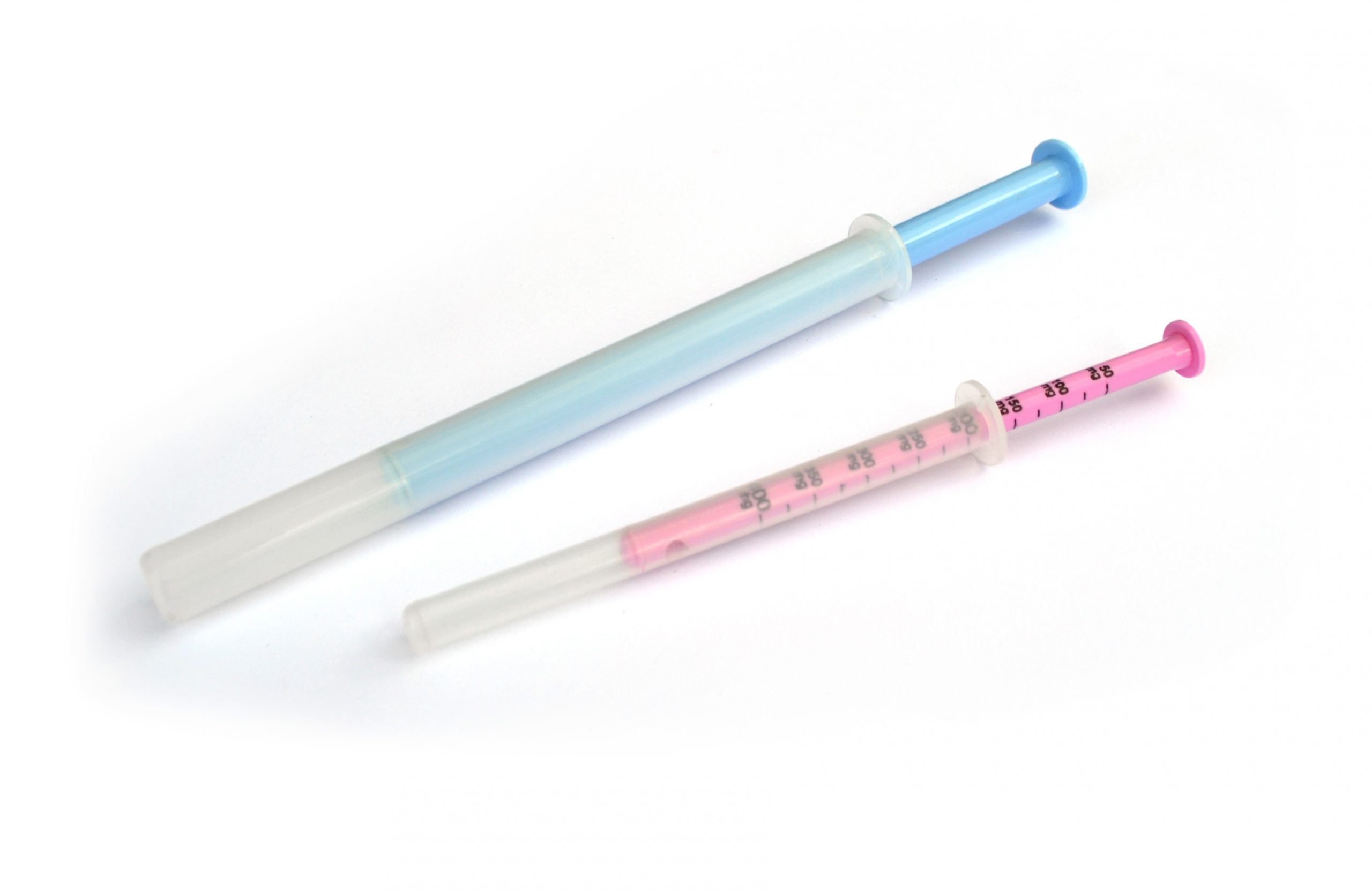

Medical Plastic Injection

We use the latest technologies and applications in the industry to provide the best results to our customers in the field of medical devices.

We effectuate our injection molding operations in ISO 8 Class 100.000 areas with auto-controlled HVAC systems.

Our advantages in injection production;

- Closed Loop Center

- Material Handling System

- Robot Automation

- Central Mold Cooling System

- Wide range of raw materials (PC, PEEK, TPE, COC, PVC, PET, PE, PP, PS, PMMA, ABS)

- Mold Maintenance and Repair Works

- Hot Runner Control Systems

- Verified Production Works under 13485 QMS

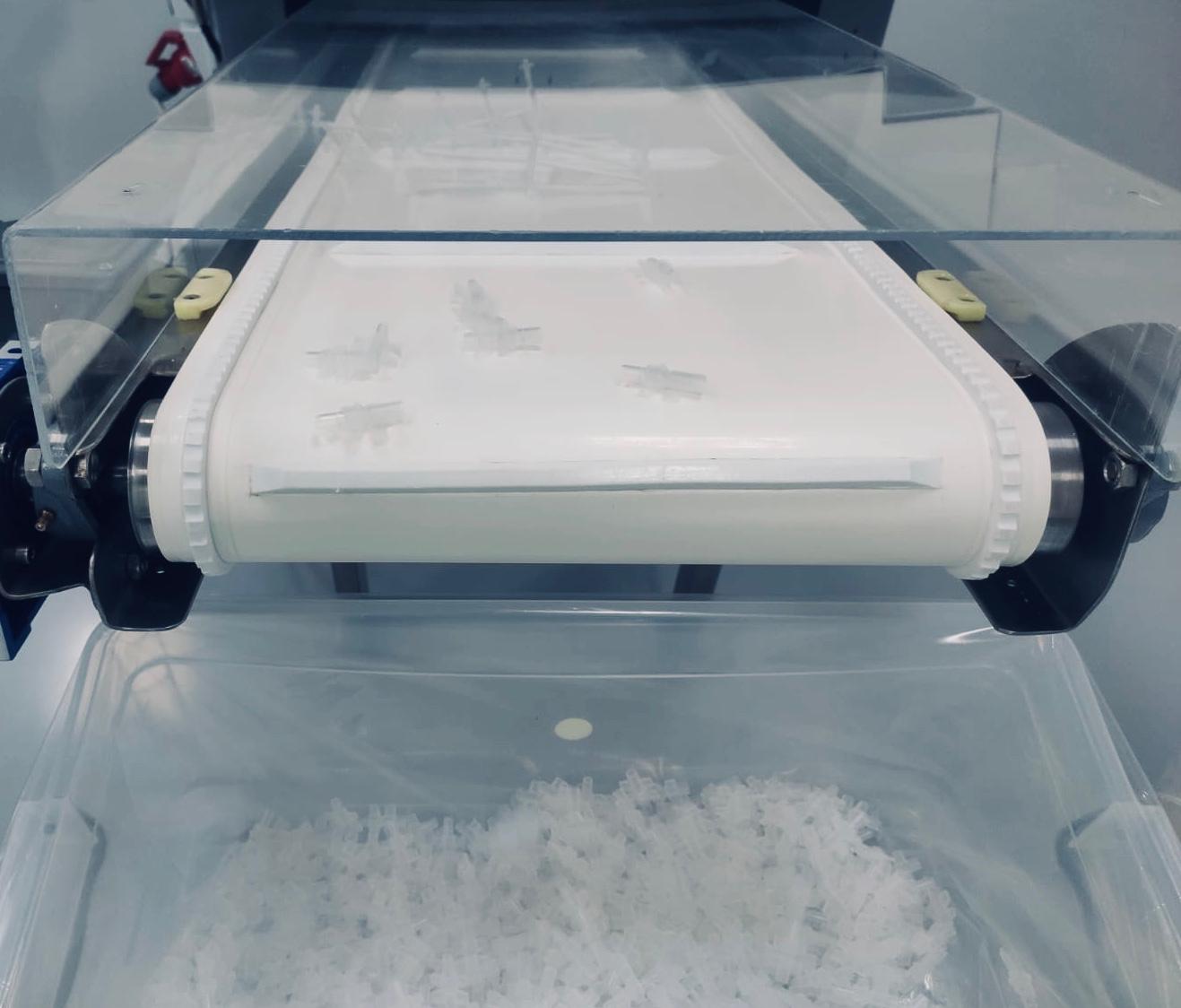

Medical Extrusion

We effectuate extrusion productions that fulfill the required specifications in various diameters and sizes for your infusion, transfusion, hemodialysis, extension sets.

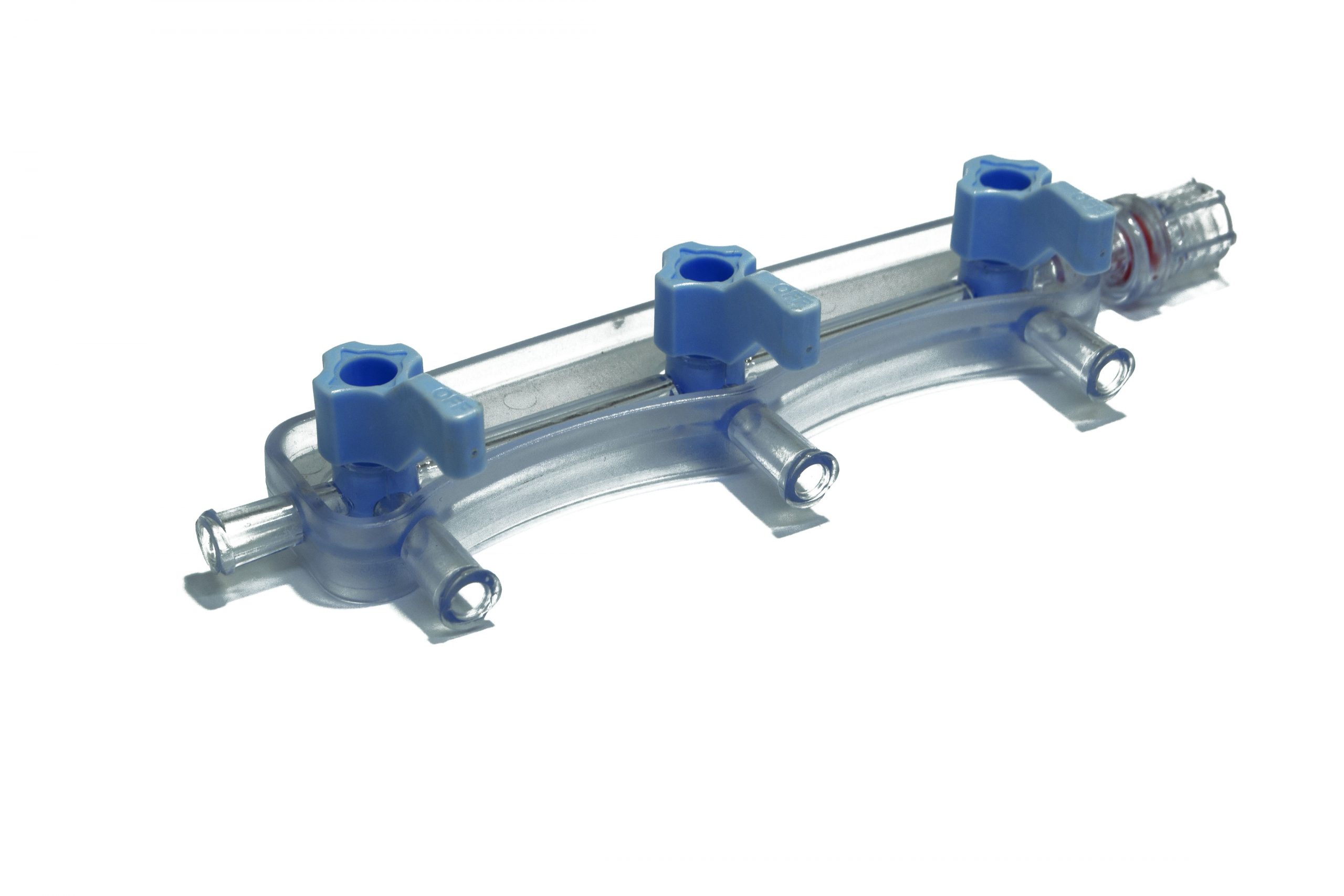

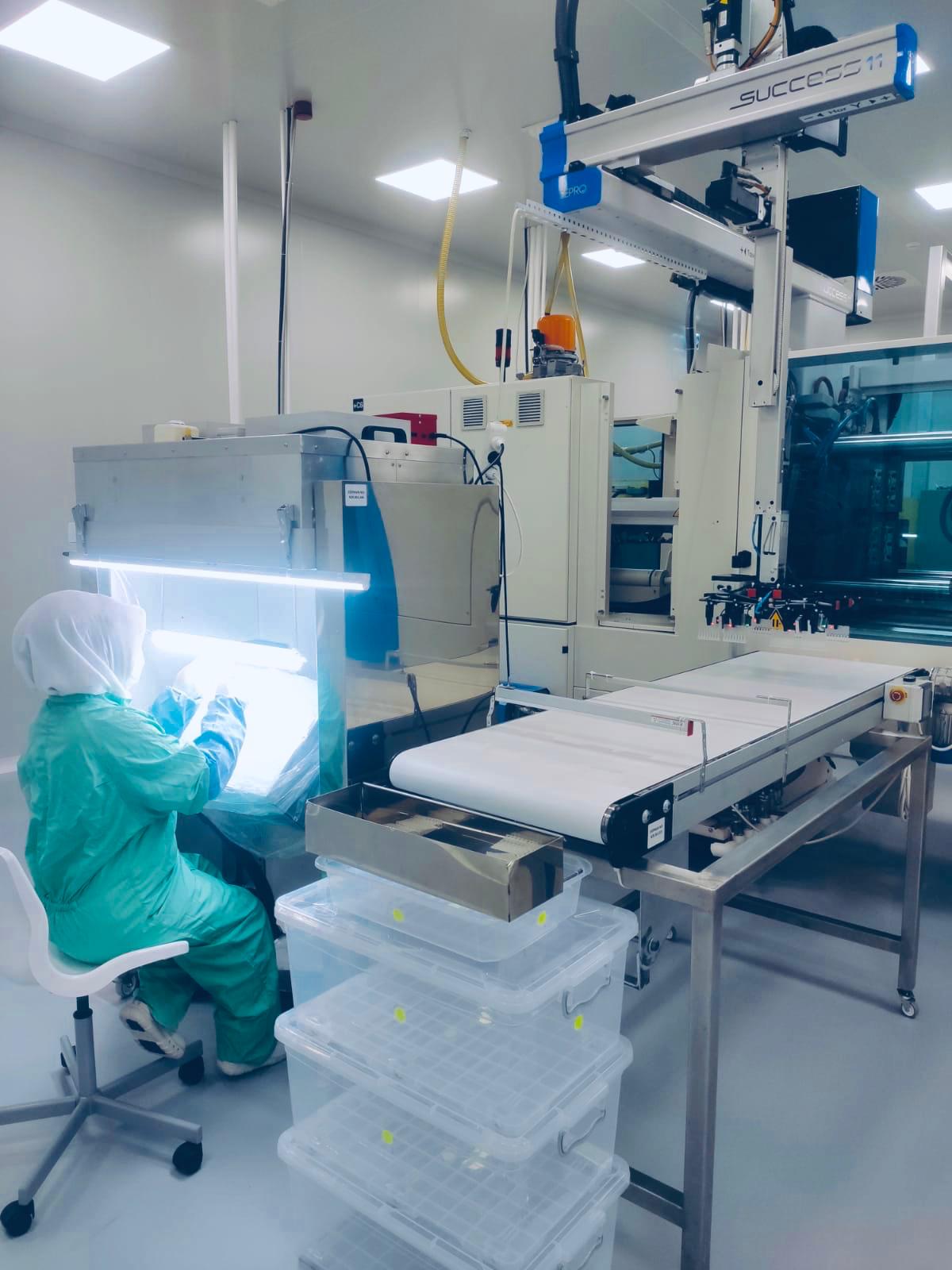

Medical Assembly and Packaging

We assemble both our own products and medical device components provided by our customers in Class 100,000 cleanroom (ISO 8) and turn them into finished products.

We use the necessary machines and devices for the assembly and packaging operation processes to be effectuated under optimum conditions.

We provide operational support for the sterilization process (GAMMA, EO, etc.) presumed appropriate by our customer if it requested.